Traditional Bamboo-bow-making process has several steps: 1:making bow body part from bamboo and wood (Fuji-banashi), 2: shaping bow (Mura-Tori), 3: painting with Japanese Urushi lacquer (needed for traditional bamboo bow made with Nibe glue in summer season).

In Japanese medieval period such as Edo Jidai, Samurai, as a Kyudo archer sometimes shaped the bow by himself. This process is called "Ite- Mura" , which means Shaping a bow by archer.

These days all the process of making the bow are done by Yumi-shi, Bow maker, but there were some bows shaped by archers when Junji Miyata was young.

Junji Miyata gradually practiced shaping the bow to see that his instructor Sakae Urakami shaped the bow. Later, Junji Miyata made the Fiber-Glass Reinforced Plastic Kyudo bow with this skills to use the handmade FRP Kyudo bow at the World Archery Championships 1967, to compete with world-class archers.

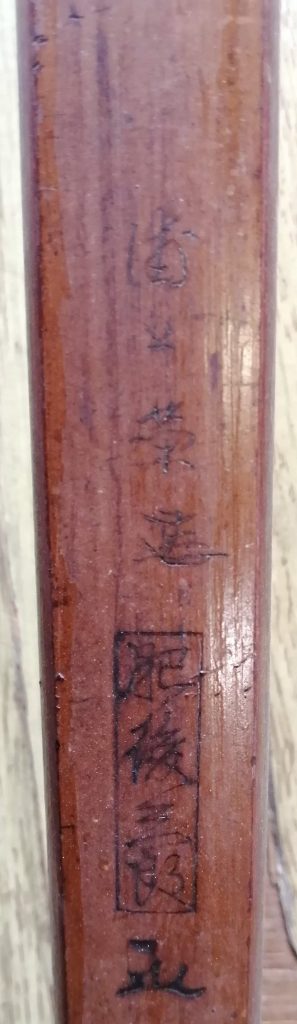

Bow made by Higo-Saburo / shaped by the master archer (Urakami, Sakae)